-

igwe anaghị agba nchara mmiri sink mmepụta akara

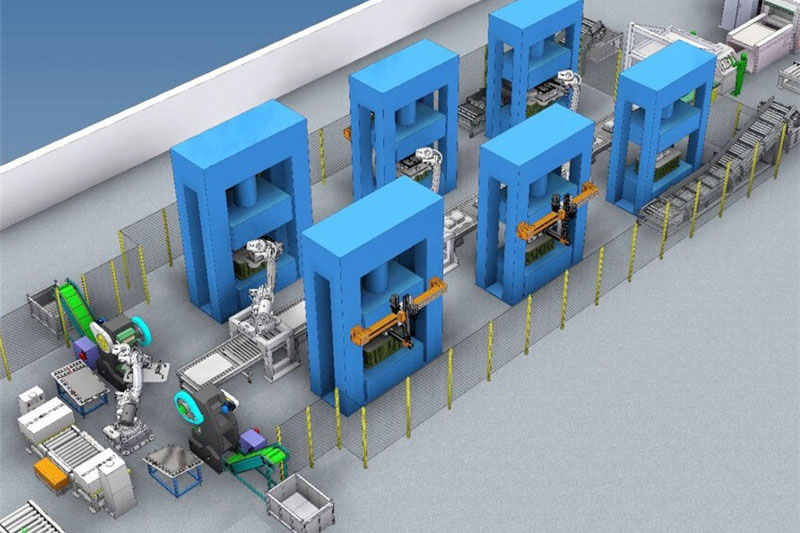

Igwe anaghị agba nchara na-emepụta ahịrị mmiri igwe anaghị agba nchara bụ ahịrị nrụpụta na-akpaghị aka nke gụnyere usoro dị ka mwepu igwe nchara, ịkpụ, na stampụ iji kpụzie sink. Ahịrị mmepụta a na-eji robots dochie ọrụ aka, na-enye ohere ịmecha nrụpụta sink na akpaaka.

The igwe anaghị agba nchara mmiri sink mmepụta akara mejupụtara abụọ isi akụkụ: ihe na-enye unit na sink stamping unit. A na-ejikọta akụkụ abụọ a site na ngalaba nnyefe ngwa agha, nke na-eme ka njem nke ihe dị n'etiti ha dị mfe. Ngalaba na-enye ihe na-agụnye akụrụngwa dị ka igwe anaghị agba nchara, ihe mkpuchi ihe nkiri, ihe nchara, ihe ncha, na stackers. Ngalaba na-ebufe ngwa agha nwere ụgbọ ibufe, ahịrị ndokọba ihe, na ahịrị nchekwa pallet efu. Ngalaba stampụ ahụ nwere usoro anọ: ịkpụ nkuku, ịgbatị isi, ịgbatị nke abụọ, mbelata ihu, nke gụnyere iji igwe igwe hydraulic na akpaaka robot.

Ike mmepụta nke ahịrị a bụ 2 iberibe kwa nkeji, yana mmepụta kwa afọ nke ihe dịka 230,000 iberibe.

-

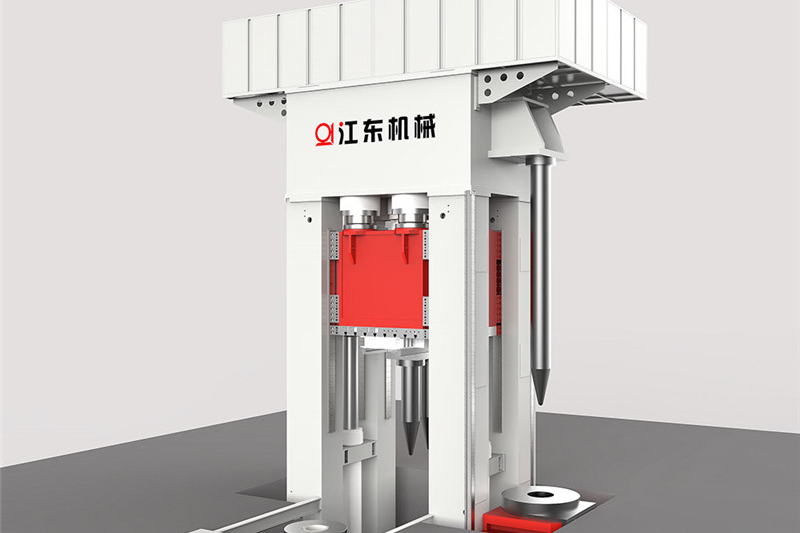

SMC/BMC/GMT/PCM Composite Molding Hydraulic Press

Iji hụ na njikwa ziri ezi n'oge a na-akpụzi ihe, a na-eji ígwè ọrụ hydraulic arụ ọrụ nwere usoro nchịkwa hydraulic servo dị elu. Usoro a na-akwalite njikwa ọnọdụ, njikwa ọsọ, njikwa ọsọ oghere micro, yana izi ezi oke nrụgide. Izi ezi njikwa nrụgide nwere ike iru ± 0.1MPa. Enwere ike ịtọ ma mezie ihe ndị dị ka ọnọdụ mmịfe, ọsọ mgbada, ọsọ tupu pịa, ọsọ oghere micro, ọsọ nloghachi na oge iyuzucha n'ime ebe ụfọdụ na ihuenyo mmetụ ahụ. Usoro nchịkwa na-azọpụta ike, na-enwe obere mkpọtụ na obere mmetụta hydraulic, na-enye nkwụsi ike dị elu.

Iji lebara teknuzu okwu dị ka enweghị itule ibu kpatara asymmetric kpụrụ akụkụ na ọkpụrụkpụ deviations na nnukwu ewepụghị mkpa ngwaahịa, ma ọ bụ izute usoro chọrọ dị ka na-ebu mkpuchi na yiri demolding, hydraulic pịa nwere ike onwem na a ike ozugbo anọ-nkuku larịị ngwaọrụ. Ngwaọrụ a na-eji ihe mmetụta mgbapụ dị elu yana valvụ valvụ nzaghachi dị elu iji chịkwaa mmemme mmezi synchronous nke ndị na-arụ ọrụ cylinder anọ. Ọ na-enweta oke nha nha nke akụkụ anọ ruo 0.05mm na tebụl dum.

-

LFT-D ogologo eriri mesiri thermoplastic mkpakọ ozugbo ịkpụzi ahịrị

The LFT-D ogologo eriri mesikwuru thermoplastic mkpakọ kpọmkwem ịkpụzi mmepụta ahịrị bụ a keukwu ngwọta maka ịrụ ọrụ nke ọma akpụ elu-edu mejupụtara ihe. Nke a mmepụta ahịrị mejupụtara a iko eriri yarn usoro eduzi, a ejima-ịghasa iko eriri plastic agwakọta extruder, a ngọngọ kpo oku ebu, a roboti ihe njikwa usoro, a ngwa ngwa hydraulic pịa, na a centralized akara unit.

Usoro mmepụta na-amalite site na ntinye eriri iko na-aga n'ihu na-eri nri n'ime extruder, ebe a na-egbutu ya ma tinye ya n'ụdị pellet. A na-ekpo ọkụ na pellets ndị ahụ ngwa ngwa na-akpụzi ha ka ọ bụrụ ọdịdị a chọrọ site na iji usoro njikwa ihe eji eme ihe na ngwa ngwa hydraulic. Na kwa afọ mmepụta ike nke 300,000 ka 400,000 ọrịa strok, a mmepụta akara ana achi achi elu arụpụtaghị.

-

Ngwa Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM).

The Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) akụrụngwa bụ ihe ngwọta na-egbu egbu nke emepụtara n'ime ụlọ maka mmepụta nke akụkụ carbon fiber dị elu. Ahịrị mmepụta a zuru oke gụnyere sistemu preforming nhọrọ, onye na-ebipụta akwụkwọ pụrụ iche HP-RTM, sistemu ịgba ọgwụ mgbanye nke HP-RTM, robotics, ebe njikwa ahịrị mmepụta, yana ebe nrụpụta nhọrọ. Sistemụ injection resin dị elu nke HP-RTM nwere sistemu mita, sistemu agụụ, sistemu njikwa ọnọdụ okpomọkụ, yana ụgbọ njem na nchekwa akụrụngwa. Ọ na-eji usoro nrụgide dị elu, na-emeghachi omume nke nwere ihe mejupụtara atọ. Ejiri usoro mgbasa ozi nwere akụkụ anọ nwere usoro nhazi ọkwa, na-enye ọkwa dị mma nke 0.05mm. Ọ na-egosipụtakwa ikike imeghe micro, na-enye ohere maka usoro mmepụta ngwa ngwa nke nkeji 3-5. Nke a na ngwá na-enyere ndị ogbe mmepụta na ahaziri mgbanwe nhazi nke carbon eriri components.

-

Mpụpụ ígwè/ọkụ anwụ na-akpụ akpụ hydraulic

Metal extrusion/hot die forging hydraulic press bụ nkà na ụzụ nrụpụta dị elu maka nhazi dị elu, ịrụ ọrụ nke ọma na nke dị ala nke ihe ígwè na-eji obere ihe na-egbutu ma ọ bụ na-enweghị. O nwetala ngwa dị ukwuu na ụlọ ọrụ mmepụta ihe dị iche iche dị ka ụgbọ ala, igwe, ụlọ ọrụ ọkụ, ikuku ikuku, nchekwa, na akụrụngwa eletrik.

Metal extrusion/na-ekpo ọkụ anwụ forging hydraulic pịa bụ kpọmkwem maka oyi extrusion, ọkụ extrusion, na-ekpo ọkụ forging, na-ekpo ọkụ anwụ forging akpụ Filiks, nakwa dị ka nkenke finishing nke metal components.

-

titanium alloy superplastic akpụ hydraulic pịa

The Superplastic Forming Hydraulic press bụ igwe pụrụ iche emebere maka nhazi netwọk dị nso nke ihe dị mgbagwoju anya nke sitere na ihe ndị siri ike na-emepụta nwere oke okpomọkụ dị warara na nrụrụ dị elu. Ọ na-achọta ngwa zuru ebe niile na ụlọ ọrụ dịka ikuku ikuku, ụgbọ elu, agha, nchekwa na ụgbọ okporo ígwè dị elu.

Igwe mmiri hydraulic a na-eji ihe ndị dị elu dị ka titanium alloys, aluminum alloys, magnesium alloys, na ihe ndị dị elu na-ekpo ọkụ, site n'ịgbanwe nha ọka nke akụrụngwa na steeti superplastic. Site n'itinye nrụgide dị ala na ọsọ ọsọ a na-achịkwa, ndị nta akụkọ na-enweta nrụrụ superplastic nke ihe. Nke a mgbanwe n'ichepụta usoro na-enyere mmepụta nke components iji budata ibu ibu tụnyere ot akpụ usoro.

-

Mpịakọta hydraulic na-akpụ akpụ n'efu

The Free Forging Hydraulic Press bụ igwe pụrụ iche emebere maka ọrụ ịgha n'efu buru ibu. Ọ na-enyere aka ịmecha usoro dị iche iche dị iche iche dị ka elongation, iwe iwe, ịkụ ọkpọ, ịgbasa, ịse mmanya, ntụgharị, ịgbagọ, ịgbanye, na ịkpụ maka mmepụta nke osisi, mkpanaka, efere, diski, mgbanaka, na ihe ndị mejupụtara okirikiri na square shapes. N'ịbụ onye ejiri ngwaọrụ inyeaka agbakwunyere dị ka igwe akpụ akpụ, sistemu eji eji ihe eji eme ihe, tebụl ihe eji eme ihe, anvils, na usoro ibuli elu, ndị nta akụkọ na-ejikọta ihe ndị a n'enweghị nsogbu ọ bụla iji mezuo usoro akpụ akpụ. Ọ na-achọta ngwa dị ukwuu na ụlọ ọrụ dị ka ikuku ikuku na ụgbọ elu, ụgbọ mmiri, mmepụta ike, ike nuklia, metallurgy, na petrochemicals.

-

Light Alloy Liquid Die Forging/semissolid forming Production Line

The Light Alloy Liquid Die Forging Production Line bụ teknụzụ ọgbara ọhụrụ nke na-ejikọta uru nke nkedo na usoro ịgha mkpụrụ iji nweta ọdịdị dị nso. Ahịrị mmepụta ihe ọhụrụ a na-enye ọtụtụ uru, gụnyere obere usoro eruba, enyi gburugburu ebe obibi, oriri ike dị ala, nhazi akụkụ otu, yana ịrụ ọrụ dị elu. Ọ mejupụtara mmiri mmiri CNC multifunctional nwụrụ anwụ na-emepụta hydraulic press, sistemu ịwụsa mmiri mmiri aluminom, igwe rọbọt na sistemu ụgbọ ala jikọtara ọnụ. Ejiri akara mmepụta ya site na njikwa CNC ya, njirimara ọgụgụ isi, na mgbanwe.

-

Ahịrị Mmepụta Gas Silinder/Mgbo Housing Drawing

A haziri Line Gas Silinder/Bullet Housing Drawing Production Line maka imepụta akụkụ nke nwere ụdị iko (barrel) nwere njedebe dị ala, dị ka igbe dị iche iche, cylinder gas, na ụlọ mgbọ. Usoro mmepụta a na-enyere usoro atọ dị mkpa aka: iwe iwe, ịkụ ọkpọ, na ịbịaru. Ọ na-agụnye akụrụngwa dị ka igwe nri, igwe ọkụ ọkụ na-ajụkarị ugboro ugboro, eriri ebufe, robot nri / aka igwe, iwe iwe na ịkụ ọkpọ hydraulic, tebụl slide ọdụ ụgbọ mmiri, nnyefe robot / aka igwe, ịse hydraulic press, na usoro nnyefe ihe.

-

Ahịrị mmepụta nke Silinda Gas Horizontal Drawing

The gas cylinder kehoraizin ịbịaru ahịrị emebere maka ịgbatị akpụ usoro nke ibu-ogologo gas cylinders. Ọ adopts a kehoraizin gbatịa akpụ Usoro, esịnede nke akara isi unit, ihe loading robot, ogologo-strok kehoraizin pịa, ihe-ịlaghachi azụ usoro, na akara ọdụ unit. Nke a mmepụta ahịrị na-enye ọtụtụ uru dị ka mfe ọrụ, elu akpụ ọsọ, ogologo ịgbatị strok, na a elu larịị nke akpaaka.

-

Gantry Straightening Hydraulic Press maka efere

A haziri gantry na-agbatị hydraulic press nke ọma maka nhazi na nhazi usoro nke efere ígwè na ụlọ ọrụ dị ka ikuku ikuku, ịrụ ụgbọ mmiri na metallurgy. Akụrụngwa ahụ nwere isi cylinder a na-ebugharị ebugharị, freema gantry mkpanaka, na tebụl arụrụ arụ. Na ike ịrụ kehoraizin displacement na ma cylinder isi na gantry frame n'ogologo nke worktable, anyị gantry straightening hydraulic pịa ana achi achi n'ụzọ ziri ezi na nke ọma efere mgbazi na-enweghị ihe ọ bụla kpuru ìsì tụrụ. A na-eji isi cylinder nke ndị nta akụkọ rụọ ọrụ na-arụ ọrụ obere mmegharị ala, na-enye ohere maka ịgbatị efere ziri ezi. Ọzọkwa, a na-emepụta tebụl ọrụ ahụ na ọtụtụ cylinder na-ebuli elu na mpaghara efere dị irè, nke na-eme ka ntinye nke mgbazigharị n'otu ebe dị iche iche ma na-enye aka n'ebuli efere ahụ.

-

Akpaaka Gantry kwụ ọtọ Hydraulic Press maka ngwaahịa mmanya

Anyị akpaka gantry na-agbatị hydraulic pịa bụ ahịrị mmepụta zuru oke nke emebere iji gbatịa nke ọma na mezie ngwaahịa igwe igwe. Ọ mejupụtara otu igwe kwụ ọtọ hydraulic mkpanaka, sistemụ njikwa nchọpụta (gụnyere nchọpụta kwụ ọtọ workpiece, nchọpụta ntụgharị akụkụ workpiece, nchọpụta anya n'ebe kwụ ọtọ, na nchọpụta mgbanwe ịgbatị), sistemu njikwa hydraulic, yana sistemụ njikwa eletriki. Igwe mmiri hydraulic a na-agbanwe agbanwe nwere ike ịmegharị usoro ịgbazinye maka ngwaahịa igwe igwe, na-ahụ maka izi ezi na arụmọrụ dị elu.