esịtidem elu nsogbu hydroforming mmepụta akara

Uru na Ngwa

The hydroforming akụrụngwa nwere ìhè arọ, ezi ngwaahịa àgwà, mgbanwe ngwaahịa imewe, mfe usoro, na nwere àgwà nke nso-net akpụ na akwụkwọ ndụ akwụkwọ ndụ n'ichepụta, n'ihi ya, ọ na-eji ọtụtụ ebe na ubi nke akpakanamde fechaa. Site n'ichepụta ngalaba dị irè na nhazi mgbidi mgbidi, ọtụtụ akụkụ ụgbọ ala nwere ike ịmepụta n'ime otu akụkụ nwere mgbagwoju anya site na hydroforming nke tubes ọkọlọtọ. O doro anya na nke a dị elu karịa usoro stampụ ọdịnala na ịgbado ọkụ n'ihe gbasara ogo ngwaahịa na ịdị mfe nke usoro mmepụta. Ọtụtụ usoro nhazi hydroforming chọrọ naanị ntụmadị (ma ọ bụ hydroforming punch) nke kwekọrọ na ọdịdị nke akụkụ ahụ, na roba diaphragm na igwe hydroforming na-arụ ọrụ nke ọnwụ na-emebu, ya mere ọnụ ahịa ọnwụ dị ihe dị ka 50% na-erughị ọnwụ ọdịnala. E jiri ya tụnyere usoro stampụ ọdịnala, nke chọrọ ọtụtụ usoro, hydroforming nwere ike ịmepụta otu akụkụ na otu nzọụkwụ.

E jiri ya tụnyere stamping ịgbado ọkụ akụkụ, uru nke ọkpọkọ hydroforming bụ: ịzọpụta ihe, mbenata ibu, n'ozuzu structural akụkụ nwere ike ibelata 20% ~ 30%, aro akụkụ nwere ike belata 30% ~ 50% : Dị ka ụgbọ ala subframe, n'ozuzu arọ nke stamping akụkụ bụ 12kg, esịtidem elu nrụgide akpụ akụkụ bụ 3g, ~ 4%, n'ihi na 3 g na-akpụ akụkụ bụ 7. stamping akụkụ arọ 16.5kg, esịtidem elu mgbali na-akpụ akụkụ bụ 11.5kg, arọ Mbelata nke 24%; Nwere ike ibelata oke ọrụ machining na ịgbado ọkụ na-esote; Mee ka ike na isi ike nke akụkụ ahụ dịkwuo elu, ma mee ka ike ọgwụgwụ dị ike n'ihi mbelata nke nkwonkwo solder. E jiri ya tụnyere akụkụ nke ịgbado ọkụ, ọnụego itinye n'ọrụ bụ 95% ~ 98%; Belata ụgwọ nrụpụta na ọnụ ahịa ebu site na 30%.

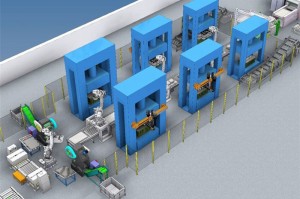

akụrụngwa hydroforming dabara adaba maka imepụta ikuku, ike nuklia, petrochemical, sistemu mmiri ọ drinkingụ ,ụ, sistemu ọkpọkọ, ụgbọ ala na ụlọ ọrụ igwe kwụ otu ebe nke akụkụ nwere oghere oghere. Ngwaahịa ndị dị na mpaghara ụgbọ ala bụ etiti nkwado ahụ ụgbọ ala, etiti inyeaka, akụkụ chassis, nkwado injin, ntinye na ikpocha sistemu ọkpọkọ, camshaft na akụkụ ndị ọzọ.

Oke ngwaahịa

| Nkịtị ike [KNI | 16000>NF>50000 | 16000 | 20000 | 25000 | 30000 | 35000 | 40000 | 50000 | |

| Ìhè ụbọchị imeghe[mm] | N'elu arịrịọ | ||||||||

| slide ọrịa strok[mm] | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1200 | ||

| Ọsọ mmịfe | Ngwa ngwa gbadata[mm/s] | ||||||||

| Na ịpị[mm/s | |||||||||

| laghachi[mm/s] | |||||||||

| Nha akwa | LR[mm] | 2000 | 2000 | 2000 | 3500 | 3500 | 3500 | 3500 | |

| FB[mm] | 1600 | 1600 | 1600 | 2500 | 2500 | 2500 | 2500 | ||

| Elu site na akwa ruo n'ala [mm] | |||||||||

| Ngụkọta moto ike [KW] | |||||||||