The elu-ọsọ ọkụ Stamping Production Line maka ultral elu-ike ígwè (Aluminom)

Njirimara isi

Emebere Line na-emepụta iji kwalite usoro mmepụta nke akụkụ ụgbọ ala site na ngwa nke teknụzụ na-ekpo ọkụ na-ekpo ọkụ. Usoro a, nke a maara dị ka stamping na-ekpo ọkụ na Asia na ịpị hardening na Europe, gụnyere ikpo ọkụ ihe efu na okpomọkụ dị iche iche wee pịa ya na ihe ndị kwekọrọ na ya site na iji teknụzụ mgbasa ozi hydraulic ka ọ na-anọgide na-arụ ọrụ iji nweta ọdịdị a chọrọ ma na-eme mgbanwe mgbanwe nke ígwè. Enwere ike ịkewa usoro ịgbanye ọkụ na-ekpo ọkụ n'ime ụzọ stamping ọkụ ozugbo na nke na-apụtachaghị ìhè.

Uru

Otu n'ime uru ndị bụ isi nke ihe nrụpụta ihe na-ekpo ọkụ na-ekpo ọkụ bụ nhazi ha dị mma, nke na-enye ohere maka ịmepụta geometrices dị mgbagwoju anya na ike nkwụsị pụrụ iche. Ike dị elu nke akụkụ ndị na-ekpo ọkụ na-ekpo ọkụ na-enyere aka iji mpempe ígwè dị nro, na-ebelata ịdị arọ nke ihe ndị dị na ya ma na-edobe iguzosi ike n'ezi ihe na arụmọrụ okuku. Uru ndị ọzọ gụnyere:

Mbelata ọrụ njikọta:Teknụzụ stampụ na-ekpo ọkụ na-ebelata mkpa ọ dị maka ịgbado ọkụ ma ọ bụ ime njikọ njikọ, na-ebute arụmọrụ ka mma yana nkwalite nrụpụta ngwaahịa.

Obere Springback na ibe akwụkwọ:Usoro stampụ na-ekpo ọkụ na-ebelata nrụrụ na-adịghị mma, dị ka akụkụ mmiri azụ azụ na warpage, na-eme ka usoro ziri ezi na-ebelata ma na-ebelata mkpa maka ịrụ ọrụ ọzọ.

Nkwarụ akụkụ ole na ole:Akụkụ ndị na-ekpo ọkụ na-ekpo ọkụ na-egosipụta ntụpọ ole na ole, dị ka mgbawa na nkewa, ma e jiri ya tụnyere ụzọ ịkpụ oyi, na-ebute mma ngwaahịa na mbelata mkpofu.

Obere Press Tonna:Stamping na-ekpo ọkụ na-ebelata ụda ntanye a chọrọ ma e jiri ya tụnyere usoro ịkpụ oyi, na-eduga n'ichekwa ego na ịba ụba mmepụta ihe.

Nhazi nke akụrụngwa:Nkà na ụzụ na-ekpo ọkụ na-ekpo ọkụ na-enye ohere maka nhazi nke ihe onwunwe na-adabere na akụkụ ụfọdụ nke akụkụ ahụ, na-eme ka arụmọrụ na arụ ọrụ dịkwuo mma.

Mmelite Microstructural emelitere:Stamping na-ekpo ọkụ na-enye ikike ịkwalite microstructure nke ihe ahụ, na-eme ka ihe ndị na-emepụta ihe na-eme ka ọ dịkwuo mma na ịba ụba ngwaahịa.

Usoro Mmepụta agbatịkwuru:Stamping na-ekpo ọkụ na-ewepụ ma ọ bụ na-ebelata usoro mmepụta ihe etiti, na-ebute usoro mmepụta dị mfe, mmepụta ihe na-emewanyewanye, na obere oge ndu.

Ngwa ngwaahịa

The High-Strength Steel (Aluminum) High-Speed Hot Stamping Production Line na-achọta ngwa ngwa n'ichepụta akụkụ ahụ na-acha ọcha akpaaka. Nke a na-agụnye mgbakọ ogidi, ihe mgbochi, oghere ọnụ ụzọ, na mgbakọ ụgbọ okporo ígwè nke a na-eji n'ụgbọ ala ndị njem. Na mgbakwunye, a na-enyochawanye ojiji nke alloys dị elu nke stampụ ọkụ na-enyere aka na ụlọ ọrụ dị ka ikuku ikuku, nchekwa na ahịa na-apụta. Alloys ndị a na-enye uru nke ike dị elu na ibelata ibu nke siri ike nweta site na ụzọ ndị ọzọ akpụ.

N'ikpeazụ, High-Strength Steel (Aluminum) High-Speed Hot Stamping Production Line na-eme ka mmepụta ahụ nke ọma na nke ọma nke akụkụ ahụ ụgbọ ala dị mgbagwoju anya. Site n'ụdị dị elu, arụ ọrụ njikọta ọnụ belatara, obere ntụpọ, yana akụrụngwa akụrụngwa emelitere, ahịrị mmepụta a na-enye ọtụtụ uru. Ngwa ya na-agbatị n'ichepụta akụkụ ahụ ọcha maka ụgbọ ala ndị njem ma na-enye uru dị na mbara igwe, nchekwa na ahịa na-apụta. Tinye ego na igwe dị elu (aluminom) High-Speed Hot Stamping Production Line iji nweta arụmọrụ pụtara ìhè, arụpụtaghị ihe na uru dị fechaa n'ime ụgbọ ala na ụlọ ọrụ jikọrọ aka.

Kedu ihe bụ stampụ ọkụ?

Hot stamping, makwaara dị ka pịa hardening na Europe na na-ekpo ọkụ pịa akpụ na Asia, bụ a usoro nke ihe na-akpụ ebe a oghere na-ewe iwe ọkụ na a ụfọdụ okpomọkụ na mgbe ahụ stampụ na quenched n'okpuru nrụgide na kwekọrọ ekwekọ anwụ imezu chọrọ udi na ime ka a na-adọ mgbanwe na metal ihe. Nkà na ụzụ na-ekpo ọkụ na-ekpo ọkụ na-agụnye ikpo ọkụ boron ígwè mpempe akwụkwọ (na ike mbụ nke 500-700 MPa) na steeti austenitizing, na-ebufe ha ngwa ngwa na anwụ maka stampụ ọsọ ọsọ, na imenyụ akụkụ ahụ n'ime ọnwụ ahụ na ọnụego jụrụ oyi karịa 27 ° C / s, na-esote oge nke ijide n'okpuru nrụgide, iji nweta ultra-high power steel .

Uru nke na-ekpo ọkụ stamping

Emelitere ike tensile kacha mma yana ikike imepụta geometry dị mgbagwoju anya.

Ewelatala ibu akụrụngwa site na iji metal mpempe akwụkwọ dị gịrịgịrị ka ọ na-edobe iguzosi ike n'ezi ihe na arụrụ ọrụ mkpọka.

Mbelata mkpa maka ijikọ ọrụ dị ka ịgbado ọkụ ma ọ bụ nchikota.

Obere akụkụ mmiri azụ na ịgbagha.

Nrụrụ akụkụ dị ole na ole dị ka mgbawa na mgbawa.

Ọdịmma pịa tonnage chọrọ ka atụnyere oyi akpụ.

Ikike ịkwa akwa ihe onwunwe dabere na mpaghara mpaghara akọwapụtara.

Microstructures emelitere maka ịrụ ọrụ ka mma.

Usoro nrụpụta Streamlined nwere obere arụmọrụ iji nweta ngwaahịa emechara.

Uru ndị a na-enye aka n'ịrụ ọrụ n'ozuzu, ịdịmma na ịrụ ọrụ nke ihe nrụpụta stampụ dị ọkụ.

Nkọwa ndị ọzọ gbasara stampụ ọkụ

1. Hot Stamping vs oyi stamping

Hot stamping bụ a akpụ usoro na-eme mgbe preheating nchara mpempe akwụkwọ, mgbe oyi stamping na-ezo aka kpọmkwem stamping nke ígwè mpempe akwụkwọ na-enweghị preheating.

Stamping oyi nwere uru doro anya karịa stampụ ọkụ. Agbanyeghị, ọ na-egosipụtakwa ụfọdụ ọghọm. N'ihi nrụgide dị elu nke usoro stampụ oyi na-ebute ma e jiri ya tụnyere ikpo ọkụ na-ekpo ọkụ, ngwaahịa oyi na-atụ oyi na-adaba na mgbawa na nkewa. Ya mere, achọrọ ngwa stampụ ziri ezi maka stampụ oyi.

Stamping na-ekpo ọkụ na-agụnye ikpokọta mpempe akwụkwọ ígwè ka ọ bụrụ okpomọkụ dị elu tupu ịkwanye stampụ na n'otu oge quenching na anwụ. Nke a na-eduga na ngbanwe zuru oke nke microstructure nchara n'ime martensite, na-ebute ike dị elu sitere na 1500 ruo 2000 MPa. N'ihi ya, ngwaahịa ndị na-ekpo ọkụ na-ekpo ọkụ na-egosipụta ike dị elu ma e jiri ya tụnyere ndị ogbo nwere oyi.

2. Hot Stamping Usoro na-aga

Stamping na-ekpo ọkụ, nke a makwaara dị ka "ịkụkọ ike," gụnyere ikpo ọkụ mpempe akwụkwọ dị elu nke nwere ike mbụ nke 500-600 MPa na okpomọkụ n'etiti 880 na 950 ° C. A na-apịsị mpempe akwụkwọ a na-ekpo ọkụ ngwa ngwa ma menyụọ na anwụ, na-enweta ọnụego jụrụ oyi nke 20-300 ° C / s. The mgbanwe nke austenite n'ime martensite n'oge quenching budata enhances ike nke akụrụngwa, ikwe ka mmepụta nke stamped akụkụ na ike nke ruo 1500 MPa.Hot stamping usoro nwere ike nkewa abụọ edemede: kpọmkwem hot stamping na indirect hot stamping:

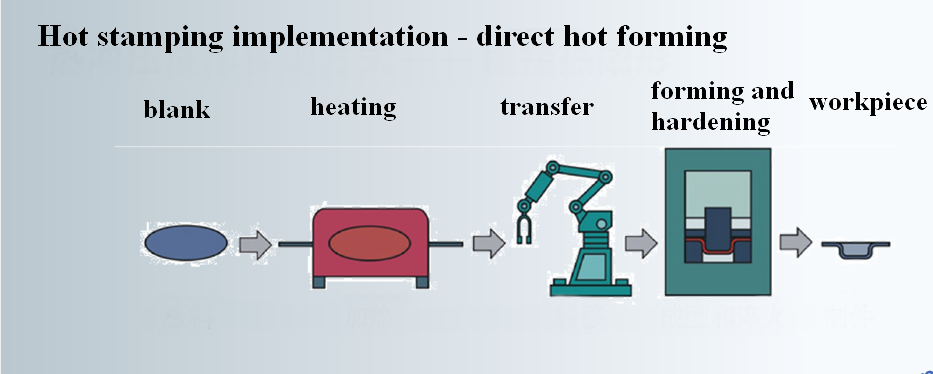

Na stampụ na-ekpo ọkụ ozugbo, a na-etinye oghere ahụ ekpo ọkụ ozugbo n'ime anwụ mechiri emechi maka stampụ na imenyụ. Usoro ndị na-esote gụnyere nju oyi, mbelata ọnụ na ịkụ ọkpọ (ma ọ bụ ịkpụ laser), na nhicha elu.

Fiture1: ọnọdụ nhazi stamping na-ekpo ọkụ - stampụ ọkụ ozugbo

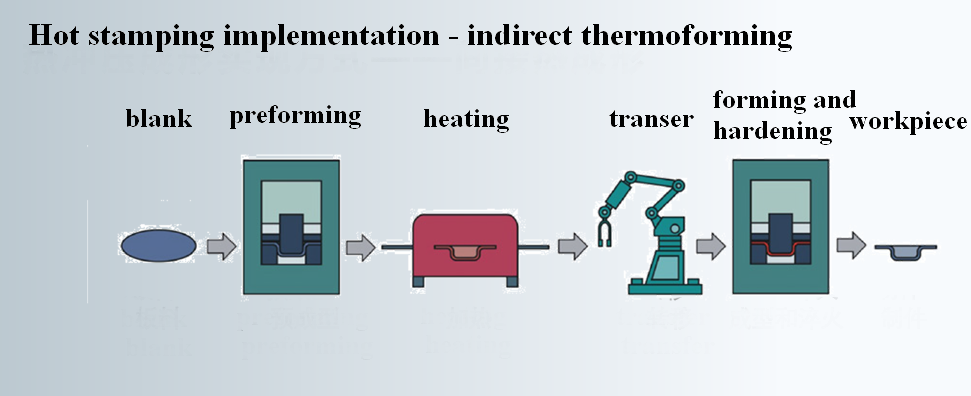

N'ime usoro ịgbanye ọkụ na-apụtaghị ìhè, a na-eme usoro ntu oyi na-akpụpụta tupu abanye n'usoro ikpo ọkụ, stamping ọkụ, mbelata ọnụ, ịkụ ọkpọ, na ihicha elu.

Isi ihe dị iche n'etiti indirect na-ekpo ọkụ stamping na kpọmkwem na-ekpo ọkụ stamping Filiks dabeere na nsonye nke oyi na-akpụ tupu shaping nzọụkwụ tupu kpo oku ke indirect usoro. Na stamping na-ekpo ọkụ kpọmkwem, a na-etinye mpempe akwụkwọ mpempe akwụkwọ ozugbo n'ime ọkụ ọkụ ọkụ, ebe na-ekpo ọkụ na-ekpo ọkụ na-apụtaghị ìhè, a na-eziga ihe ndị na-eme ka oyi na-atụ na-eme ka ọ bụrụ ihe a na-emepụta n'ime ọkụ ọkụ.

Usoro eruba nke stampụ ọkụ na-apụtaghị ìhè na-agụnye usoro ndị a:

Oyi na-akpụzi tupu akpụzi--ọkụ-stamping na-ekpo ọkụ-- mkpụcha ọnụ na ịpị oghere-ihicha elu.

Fiture2: ọnọdụ nhazi stamping na-ekpo ọkụ - stampụ ọkụ na-apụtaghị ìhè

3.The isi akụrụngwa maka na-ekpo ọkụ stamping na-agụnye a kpo oku ọkụ, ọkụ akpụ pịa, na-ekpo ọkụ stamping ebu.

Igwe ọkụ ọkụ:

A na-eji ọkụ ọkụ na-ekpo ọkụ na-ekpo ọkụ na ike ịchịkwa okpomọkụ. Ọ nwere ike ikpo ọkụ efere dị elu na recrystallization okpomọkụ n'ime oge a kapịrị ọnụ, na-enweta ọnọdụ austenitic. Ọ kwesịrị ka enwe ike ime mgbanwe maka nnukwu ihe achọrọ mmepụta ihe na-aga n'ihu na-akpaghị aka. Ebe ọ bụ naanị igwe rọbọt ma ọ bụ ogwe aka arụrụ arụ nwere ike ijikwa billet ekpo ọkụ, ọkụ ahụ na-achọ ntinye akpaaka na ibutu ya na ezigbo ọnọdụ ọnọdụ. Na mgbakwunye, mgbe ị na-ekpo ọkụ efere ígwè anaghị ekpuchi ya, ọ kwesịrị inye nchebe gas iji gbochie oxidation elu na decarbonization nke billet.

Igwe ọkụ na-emepụta ọkụ:

Akwụkwọ akụkọ bụ isi nke teknụzụ stamping na-ekpo ọkụ. Ọ kwesịrị inwe ikike maka stamping na njide ngwa ngwa, yana kwadebere ya na usoro jụrụ oyi ngwa ngwa. Ịdị mgbagwoju anya nke igwe igwe na-ekpo ọkụ na-akpụ akpụ karịrị nke igwe igwe na-akụ oyi. Ka ọ dị ugbu a, ọ bụ nanị ụlọ ọrụ mba ọzọ ole na ole ji nkà na ụzụ na-emepụta ihe na nkà na ụzụ nke ígwè obibi akwụkwọ dị otú ahụ, na ha nile dabeere na mbubata, na-eme ka ha dị oké ọnụ ahịa.

Ụdị Stamping Na-ekpo ọkụ:

Ụdị stamping na-ekpo ọkụ na-arụ ọrụ ma na-akpụpụta ma na-ekpochapụ. N'oge a na-akpụ akpụ, ozugbo etinyere billet ahụ n'ime oghere ebu, ebu ahụ na-emecha usoro stampụ ngwa ngwa iji hụ na emechachara akụkụ ahụ tupu ihe ahụ emee mgbanwe nke Martensitic. Mgbe ahụ, ọ na-abanye na quenching na obi jụrụ ogbo, ebe okpomọkụ si workpiece n'ime ebu na-anọgide na-ebufe ebu. Ọkpụkpọ jụrụ oyi nke edobere n'ime ebu ahụ na-ewepụ ọkụ ozugbo site na oyi na-eru. Mgbanwe nke martensitic-austenitic na-amalite mgbe ọnọdụ okpomọkụ na-adaba na 425 ° C. Mgbanwe n'etiti martensite na austenite na-akwụsị mgbe okpomọkụ ruru 280 Celsius C, a na-ewepụkwa ọrụ ahụ na 200 Celsius. Ọrụ nke njide ebu bụ iji gbochie mgbasawanye ọkụ na-enweghị isi n'oge usoro nkwụsịtụ, nke nwere ike ịkpata mgbanwe dị ukwuu na ọdịdị na akụkụ nke akụkụ ahụ, na-eduga na nsị. Na mgbakwunye, ọ na-eme ka nrụpụta ọkụ dị n'etiti workpiece na ebu, na-akwalite nkwụsị ngwa ngwa na jụrụ oyi.

Na nchịkọta, ndị isi akụrụngwa maka na-ekpo ọkụ stamping na-agụnye a kpo oku oku maka ọbọ chọrọ okpomọkụ, a na-ekpo ọkụ akpụ pịa maka ngwa ngwa stamping na ijide na a ngwa ngwa jụrụ usoro, na-ekpo ọkụ stamping ebu nke na-arụ ma na-akpụ na quenching nkebi iji hụ na akụkụ kwesịrị ekwesị e guzobere na nke ọma jụrụ.

The quenching jụrụ ọsọ ọ bụghị nanị na-emetụta mmepụta oge, ma na-emetụta ntughari arụmọrụ n'etiti austenite na martensite. Ọnụego jụrụ oyi na-ekpebi ụdị ụdị kristal a ga-emepụta ma jikọta ya na mmetụta ikpeazụ ike nke workpiece. Okpomọkụ dị jụụ nke boron ígwè dị ihe dị ka 30 ℃ / s, yana naanị mgbe ọnụego jụrụ oyi gafere oke oyi, enwere ike ịkwalite nguzobe nke martensitic ruo oke. Mgbe ọnụego jụrụ oyi na-erughị ọnụego jụrụ oyi dị oke egwu, ihe ndị na-abụghị martensitic dị ka bainite ga-apụta n'ụdị crystallization workpiece. Otú ọ dị, ọnụ ọgụgụ dị elu nke dị jụụ, nke ka mma, ọnụ ọgụgụ dị elu dị elu ga-eduga na mgbawa nke akụkụ ndị a kpụrụ, na ọnụ ọgụgụ dị jụụ kwesịrị ekwesị kwesịrị ikpebi dịka ihe mejupụtara ihe na usoro nhazi nke akụkụ ahụ.

Ebe ọ bụ na imewe nke dị jụụ ọkpọkọ na-metụtara kpọmkwem size nke jụrụ ọsọ ọsọ, na jụrụ ọkpọkọ n'ozuzu haziri site n'echiche nke kacha okpomọkụ nyefe arụmọrụ, otú ntụziaka nke e mere jụrụ ọkpọkọ bụ ihe mgbagwoju anya, na ọ na-esiri ike inweta site n'ibu mkpọpu ihe mgbe ẹkụre nke ebu nkedo. Ka ịzenarị mmachi site na nhazi igwe, a na-ahọrọ usoro nke idokwa ọwa mmiri tupu ịkwanye ihe nkedo.

N'ihi na ọ na-arụ ọrụ ruo ogologo oge na 200 ℃ na 880 ~ 950 ℃ n'okpuru oké oyi na-ekpo ọkụ alternating ọnọdụ, na-ekpo ọkụ stamping anwụ ihe onwunwe ga-enwe ezi structural rigidity na thermal conductivity, na ike iguzogide ike thermal esemokwu eme site billet na elu okpomọkụ na abrasive eyi mmetụta nke particles oxide oyi akwa . Na mgbakwunye, ihe ebu ahụ kwesịkwara inwe ezigbo nguzogide corrosion na coolant iji hụ na ọ na-aga nke ọma nke ọkpọkọ jụrụ oyi.

Ịkpụcha na ịkpọpu ya

N'ihi na ike nke akụkụ mgbe na-ekpo ọkụ stamping ruru banyere 1500MPa, ma ọ bụrụ na pịa ịcha na punching na-eji, na ngwá tonnage chọrọ bụ ibu, na anwụ ọnwụ n'ọnụ iyi dị oké njọ. Ya mere, a na-ejikarị akụkụ ịkpụ laser eme ihe iji belata ọnụ na oghere.

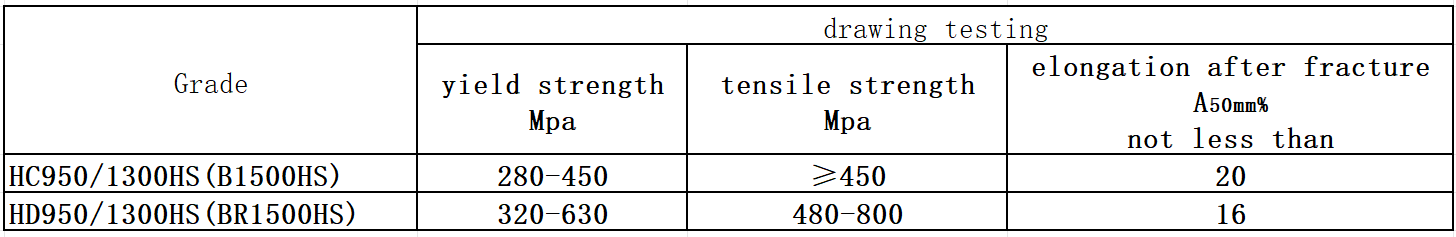

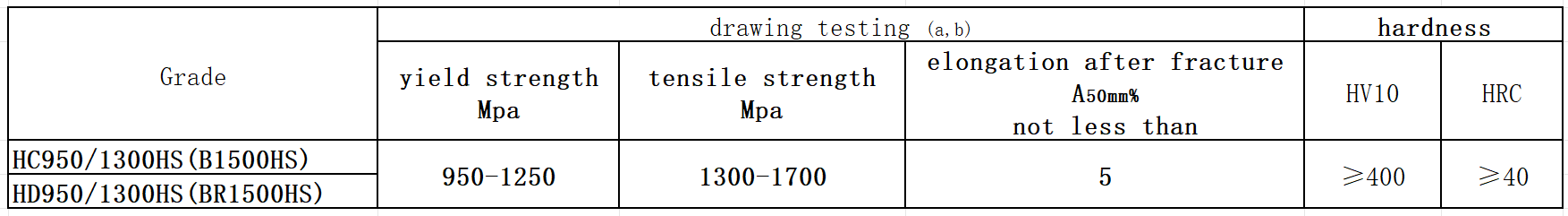

4.Common akara ule nke na-ekpo ọkụ stamping ígwè

Arụmọrụ tupu stampụ

Arụmọrụ mgbe stampụ

Ugbu a, ọkwa nkịtị nke igwe na-ekpo ọkụ bụ B1500HS. The tensile ike tupu stamping bụ n'ozuzu n'etiti 480-800MPa, na mgbe stamping ike tensile ike iru 1300-1700MPa. Nke ahụ bụ, ike ike nke 480-800MPa ígwè efere, site na-ekpo ọkụ stamping akpụ, nwere ike nweta ike tensile nke banyere 1300-1700MPa akụkụ.

5.The ojiji nke na-ekpo ọkụ stamping ígwè

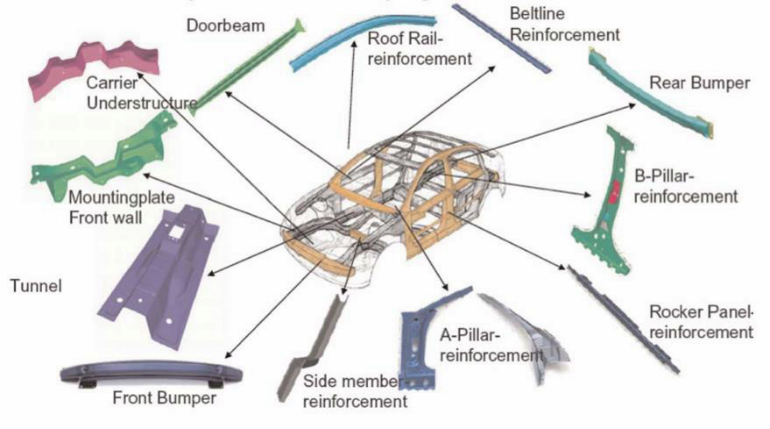

Ngwa nke akụkụ stamping na-ekpo ọkụ nwere ike imeziwanye nchekwa nke ụgbọ ala ma ghọta ịdị arọ nke ahụ ụgbọ ala na-acha ọcha. Ka ọ dị ugbu a, a na-etinye teknụzụ na-ekpo ọkụ na-ekpo ọkụ na akụkụ ahụ na-acha ọcha nke ụgbọ ala ndị njem, dị ka ụgbọ ala, A ogidi, B ogidi, bompa, oghere ọnụ ụzọ na okporo ígwè ụlọ na akụkụ ndị ọzọ. Lee ọnụ ọgụgụ 3 dị n'okpuru ebe a dịka akụkụ ndị kwesịrị ekwesị maka ịdị arọ.

ọgụgụ 3: White body components kwesịrị ekwesị maka ọkụ stamping

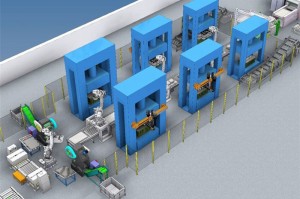

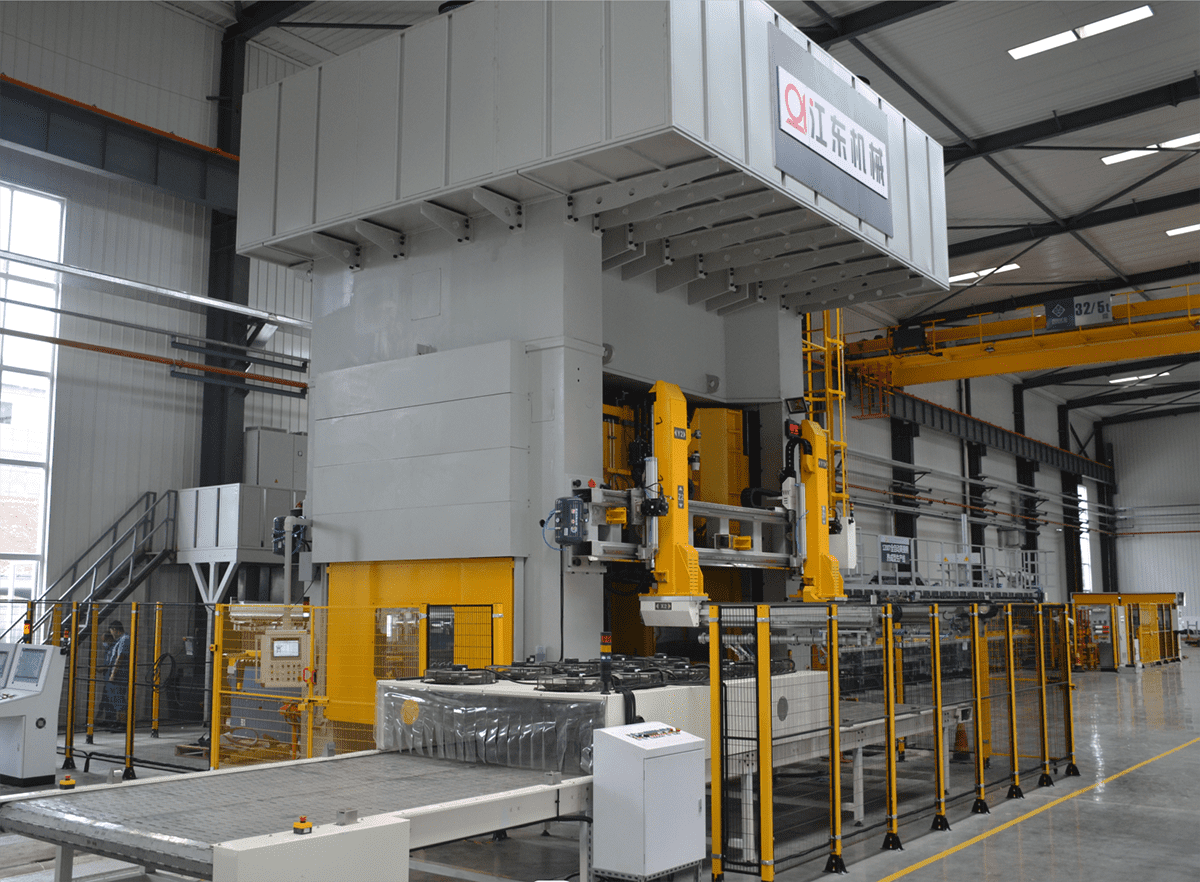

Foto 4: igwe jiangdong 1200 Ton Hot Stamping Press Line

Ugbu a, JIANGDONG Machine hot stamping haịdrọlik pịa mmepụta akara ngwọta ndidi nnọọ tozuru okè ma kwụsie ike, na China na-ekpo ọkụ stamping akpụ ubi bụ nke na-eduga larịị, na dị ka China Machine Tool Association forging machinery alaka ụlọ ọrụ osote onyeisi oche unit nakwa dị ka otu nkeji nke China Forging Machinery Standardization Committee, anyị nwekwara mere nnyocha na ngwa na-arụ ọrụ nke aluminom na-ekpo ọkụ na-arụ ọrụ nke nnukwu aluminom nke mba. na-akwalite mmepe nke ụlọ ọrụ stamping na-ekpo ọkụ na China na ọbụna ụwa.